Description

FREUD LI25M CONICAL SCORING SAW BLADES

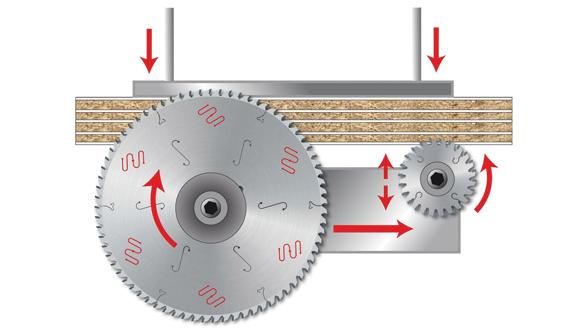

Introducing the FREUD LI25M Conical Scoring Saw Blades the perfect solution for all your woodworking needs! This high-quality saw blade is designed to produce crisp, clean cuts with minimal tear-out, making it an essential tool for any professional woodworker or DIY enthusiast.

Made from premium-quality materials and crafted with precision, the FREUD LI25M Conical Scoring Saw Blade features a unique conical shape that provides exceptional stability and accuracy during use. This innovative design ensures that the blade remains perfectly aligned and delivers smooth, consistent cut every time.

Whether you’re working with hardwoods, softwoods, laminates, or composite materials, the FREUD LI25M Conical Scoring Saw Blade is up to the task. Its sharp teeth and durable consttiction enable it to handle even the toughest cutting jobs with ease, while its advanced design ensures that it produces minimal vibration and noise.

In addition to its superior performance, the FREUD LI25M Conical Scoring Saw Blade is also incredibly easy to use. Its universal arbor size makes it compatible with a wide tange of saws, while its simple installation process allows you to get up and running in no time.

So why settle for subpar results when you can achieve professional-quality cuts with the FREUD LI25M Conical Scoring Saw Blade? Order yours today and experience the difference for yourself!

Benefits & Features

|

Silver I.C.E Coating

A high performing and anticorrosive coating to maintain the blade temperature low during the working process. The non-stick feature improves chip ejection and notably reduces resin build-up, significantly reducing friction and extending the lifetime of the blade. |

||

|

TiCo Carbide Technology

A specially formulated, highly compact Titanium Cobalt Carbide, engineered and manufactured by Freud. It provides a sharper edge and a flawless finish with a dramatically longer cutting life |

Graphs

|

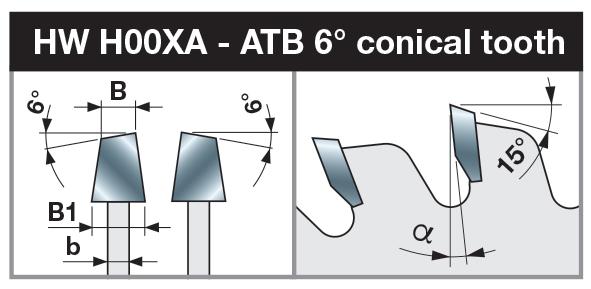

A = Minimum keft of the scorer saw blade.

B = Maximum kerf of the scorer saw blade. |

|

For each 1mm height displacement the cut becomes 0.25mm wider. |

|

|