- Home

- Product

Machine Categories

- Reciprocating Air Compressor

- Screw Air Compressor

- Oil Less Air Compressor

- Portable Air Compressor

- Air Dryer

Brands

- Contacts

- About Us

Laminated Panels

If you are working with laminated panels, it is important to use the right saw blades for the job. Here are some key features of saw blades for laminated series :

- Tooth Geometry: Saw blades for laminated series are designed with a special tooth geometry that is optimised for cutting through layers of paper or fabric or resin. The teeth are typically set a steep angle to reduce the risk of chipping or cracking the panel.

- Carbide Tips: The saw blades are made with high-quality carbide tips that are durable and long-lasting. The carbide is specially formulated for cutting through laminated materials, ensuring clean and precise cuts.

- Expansion Slots: Saw blades for laminated series typically feature expansion slots that reduce vibration and noise during cutting. This ensures that the blade stays cool and extends its lifespan.

- Non-Stick Coating: Some saw blade come with a non-stick coating that prevents resin buildup on the blade, reducing the risk of kickback and ensuring safe operation.

- Compatibility: Saw blades for laminated series are compatible with a range of saws, including table saws, miter saws, and circular saws.

When selecting a saw blade for laminated series, it is important to consider the type of material you will be cutting, the thickness of the material, and the type of the saw you will be using. A high-quality saw blade will ensure that your cuts are clean and precise, and that your panels remain intact throughout the cutting process.

Showing all 8 results

-

FREUDWhatsapp Us

FREUD LSB X INDUSTRIAL PANEL SIZING SAW BLADES

FREUD LSB X INDUSTRIAL PANEL SIZING SAW BLADE

FREUD LSB X range represents the ideal choice for industrial panel sizing. Saw Blade suitable for chipboard and MDF bi-laminated panels. Good finishing also in HPL and acrylic panel cutting.

Machines : Horizontal Panel Sizing Machines

Materials : Laminated Chipboard, Laminated MDF, HPL, Thermoplastic Composites, Plexiglas

Applications : Industrial Panel Sizing.

-

FREUDWhatsapp Us

FREUD LI16M ADJUSTABLE SCORING SAW BLADES

FREUD LI16M ADJUSTABLE SCORING SAW BLADES

FREUD LI16M Adjustable Scoring Saw Blade – To score the coaitng on bi-laminated panels.

Machines : Squaring Saws.

Materials : Laminated Chipboard, Laminated MDF.

Applications : Panel Scoring.

-

FREUDWhatsapp Us

FREUD LI25M CONICAL SCORING SAW BLADES

FREUD LI25M CONICAL SCORING SAW BLADES

FREUD LI25m Conical Scoring Saw Blades to score the coating on bi-laminated panels.

Machines : Horizontal Panel Sizing Machines, Squaring Saws.

Materials : Laminated Chipboard, Laminated MDF.

Applications : Panel Scoring.

-

FREUDWhatsapp Us

FREUD LU34M SAW BLADE FOR GROOVING AND SIZING ON CNC UNITS

FREUD LU34M SAW BLADE FOR GROOVING AND SIZING ON CNC UNITS

FREUD LU34M Saw Blade to CNC machines. For grooving along and across grain on softwood, hardwood and laminates.

Machines : CNC cutting Units

Materials : Softwood, Hardwood, Laminated Chipboard, Laminated MDF, Plywood.

Applications : Sizing on CNC, ripping, crosscutting, grooving on CNC.

-

FREUDWhatsapp Us

FREUD LU3E SAW BLADE TO CUT BI-LAMINATED PANELS

FREUD LU3E SAW BLADE

FREUD LU3E Saw Blade to cut bi-laminted Panels. To size chipboard and MDF bi-laminted panels with thickness up to 40mm. In details, it is suitable to work melamine-coated panels. No scoring saw blades needed.

Machines : Squaring saws, Horizontal Panel Sizing Machines, Vertical Panel Sizing Machines.

Materials : Laminated Chipboard, Laminated MDF.

Applications : Panel sizing.

-

FREUDWhatsapp Us

FREUD LU3D SAW BLADE TO CUT BI-LAMINATED PANELS

FREUD LU3D SAW BLADE

FREUD LU3D Saw Blade to cut Bi-Laminated Panels. To size chipboard and MDF bi-laminated panels with the use of the scoring saw blade. in detail melamine-coated panels, with good finishing and long cutting file.

Machines : Squaring saws.

Materials : Wood Based Panels, Laminated Chipboard, MDF, and Laminated MDF.

Applications : Panel sizing.

-

FREUDWhatsapp Us

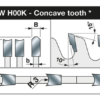

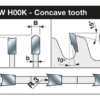

FREUD LU3B SAW BLADE TO CUT BI-LAMINATED PANELS

FREUD LU3B SAW BLADE

FREUD LU3B Saw Blade – Flat – triple chip tooth with concave face and positive cutting angle.

Machines : Squaring saws and vertical panel sizing machines.

Materials : Plywood, laminated chipboard, and laminated MDF.

Applications : Panel sizing.

-

FREUDWhatsapp Us

FREUD LU3A SAW BLADE TO CUT BI-LAMINATED PANELS

FREUD LU3A SAW BLADE

Freud LU3A Saw Blade to cut bi-laminated panels. To size chipboard and MDF bi-laminated panels. The ATB 38º tooth geometry grants perfect finishing on both side. No scoring saw blades needed.

Machines : Squaring saws and vertical panel sizing machines, hand-held circular saw.

Materials : Laminated chipboard, laminated MDF and plywood.

Applications : Panel sizing.